China Laboratory Glassware Instrument Cleaner Automatic Glassware Washer Disinfector

Product Description

Laboratory washer with two doors can open in clean and non-clean areas

Product Description

Product Description:

Rising-F1 Laboratory glassware washer,Double door design,It can be connected with tap water & pure water. The standard process is to use tap water & detergent to do mainly wash, then use Pure water rinsing, it will bring you a convenient and fast cleaning effect. When you have drying requirements for cleaned utensils, please choose Rising-F1.

Quick Details

| Brand Name: | XPZ | Model Number: | Rising-F1 |

| Place of Origin: | Hangzhou,China | Overall Power Consumption: | 40KW |

| Washing Chamber Volume: | 480L | Material: | Inner Chamber 316L/Shell 304 |

| Water Consumption/Cycle: | 45L | Power Consumption-Water Heating: | 27KW |

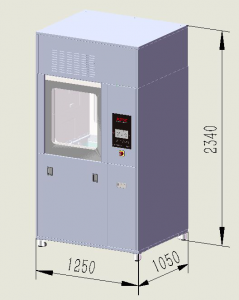

| Washer Chamber Size(H*W*D)mm: | 1067*657*800mm | External Size(H*W*D)mm: | 2000*1250*1105mm |

| Gross Weight(kg): | 730kg |

Packaging&Delivery

Packaging&Delivery

| Packaging Details | Wooden Package |

| Port | Shanghai,China |

Our Advantages

Automatic Glassware Washer

Features:

1. Can be standardized for cleaning to ensure uniform cleaning results and reduce uncertainties in human operation.

2. Easy to verify and save records for easy traceability management.

3. Reduce staff risk and avoid injury or infection during manual cleaning.

4. Cleaning, disinfection, drying and automatic completion, reducing equipment and labor input, saving costs

——-Normal washing procedure

Pre-washing → washing with Alkaline detergent under 80°C → rinse with Acid detergent →rinse with tap water → rinse with pure water→rinse with pure water under 75°C→drying

Efficient drying

1.In situ drying system

2. Built-in HEPA high efficiency filter to ensure the cleanliness of dry air;

3. Synchronize the drying water circulation pipeline to avoid the pipeline contamination of the cleaning system;

4. Double temperature control to ensure drying temperature;

Operation management

1.Wash Start delay function: The instrument comes with appointment time start & timer start function to improve the customer’s work efficiency;

2. OLED module color display, self-illumination, high contrast, no viewing angle limitation

4.3 level password management, which can meet the use of different management rights;

5. Equipment fault self-diagnosis and sound, text prompts;

6. Cleaning data automatic storage function (optional);

7.USB cleaning data export function (optional);

8. Micro printer data printing function (optional)

With high-pressure spray cleaning function, that is, spray arm flow rate induction control system, the bottle Laboratory Washer can automatically identify the loaded basket system, and accurately control the speed of the spray arm in the cleaning chamber. If the loading is wrong, the bottle washer detects the error at the beginning of the program and suspends the work. During the cleaning process, the bottle washing machine detects the speed of the spray arm to ensure that the speed is within the set range, so as to achieve a better cleaning effect.

The cleaning agent liquid volume monitoring and control system increases the safety of the system. When adding detergent chemistry, the system shields the effects of liquid viscosity and ambient temperature on liquid flow characteristics, enabling more precise liquid volume distribution. The simple flowmeter control method used in the past was affected by environmental factors. The new technology of the bottle washer has greater accuracy and safety.

During the cleaning process, even a very small residue in pure water can seriously affect the cleaning results. The bottle washer sets the system alarm function, if the conductivity in the last cleaning session exceeds the customer’s set value, the equipment will automatically re-wash. The new maintenance-free online conductivity monitoring system from the bottle washer eliminates the need for additional costs for maintenance and calibration. The system is integrated in the water circulation pathway and does not have direct contact with the water system, which is very accurate.

Automatic glassware washer—principle

With tap water and pure water (or softened water) as the working medium, using a specific cleaning agent, driven by the circulation pump, the cleaning liquid is directly washed 360 ° inside and outside the vessel by rotating the spray arm and the spray pipe, so as to peel off, emulsify and decompose the remaining substances on the vessel under the action of mechanical and chemical forces; In addition, the cleaning liquid can be automatically heated, and then the utensils can be hot cleaned and disinfected to achieve a better cleaning effect. If the model with drying function is selected, the sample bottle can also be hot air dried after washing to avoid secondary contamination caused by not being removed in time.

Specification:

| Basic Data | Functional Parameter | ||

| Model | Rising-F1 | Model | Rising-F1 |

| Power Supply | 380V | Automatic double door system | Yes |

| Material | Inner Chamber 316L/Shell 304 | ICA Module | Yes |

| Total Power | 38KW | Peristaltic Pump | ≥2 |

| Heating Power | 27KW | Condensing Unit | Yes |

| Drying Power | ≥1KW | Custom Program | Yes |

| Washing Temp. | 50-93ºC | 7 inch screen | Yes |

| Washing Chamber Volume | ≥480L | RS232 Printing Interface | Yes |

| Cleaning Procedures | ≥35 | Built-in printer | Optional |

| The Layer Number of Cleaning | 5 layers | Conductivity Monitoring | Optional |

| Pump Washing Rate | ≥1300L/min | Internet of Things | Optional |

| Weight | 730KG | Dimension(H*W*D)mm | 2000*1250*1105mm |

| Inner cavity size (H*W*D)mm | 1067*657*800mm | ||

Company Profile

Hangzhou Xipingzhe Biological Technology Co., Ltd

Hangzhou Xipingzhe Biological Technology Co., Ltd

XPZ is a leading manufacture of laboratory glassware washer,located in hangzhou city,zhejiang province,china.XPZ specializes in research,production and trade the automatic glassware washer which is applied to Bio-pharma,Medical health,Quality inspection environment ,food monitoring,and petrochemical field.

XPZ is committed to help solve all kinds of cleaning problems.We are the main supplier to Chinese inspection authorities and chemical enterprises,meanwhile XPZ brand has been spread to many other countries,like india ,UK,Russia,South Korea,Uganda,the philippinese etc.,XPZ provides integrated solutions based on customized demand,including product selection ,installation and operate training etc.

We will gather more enterprise advantage to provide innovtive products with high quality and excellent service ,to keep our long-term friendship.

Exhibition

Certifications