laboratory glassware washer; automatic glassware washer

Our pursuit and company purpose is always to “Always satisfy our consumer requirements”. We keep on to acquire and style and design remarkable high-quality products for each our outdated and new customers and reach a win-win prospect for our consumers as well as us for laboratory glassware washer; automatic glassware washer, Make Values,Serving Customer!” is definitely the purpose we pursue. We sincerely hope that all consumers will build long-lasting and mutually valuable cooperation with us.Should you wish to get extra details about our business, Please get hold of with us now.

Our pursuit and company purpose is always to “Always satisfy our consumer requirements”. We keep on to acquire and style and design remarkable high-quality products for each our outdated and new customers and reach a win-win prospect for our consumers as well as us for China Glassware Washer, Washer, Abiding by our motto of “Hold well the quality and services, Customers Satisfaction”, So we offer our clients with high quality products and excellent service. Make sure you feel free to contact us for further information.

Three levels glassware washer with Modular basket design

Product Details

Overview

Product Description:

Flash-1/F1 Laboratory glassware washer,Three – layers cleaning independent installation,It can be connected with tap water & pure water. The standard process is to use tap water & detergent to do mainly wash, then use Pure water rinsing, it will bring you a convenient and fast cleaning effect. When you have drying requirements for cleaned utensils, please choose Flash-F1.

Quick Details

| Brand Name: | XPZ | Model Number: | Flash-F1 |

| Place of Origin: | Hangzhou,China | Overall Power Consumption: | 10KW or 24KW |

| Washing Chamber Volume: | 308L | Material: | Inner Chamber 316L/Shell 304 |

| Water Consumption/Cycle: | 23L | Power Consumption-Water Heating: | 4KW or 18KW |

| Washer Chamber Size(H*W*D)mm: | 990*540*550mm | External Size(H*W*D)mm: | 1385*935*775mm |

| Gross Weight(kg): | 225kg |

Packaging&Delivery

Packaging Details Wooden Package

Port Shanghai

Automatic Glassware Washer

Features:

1. Can be standardized for cleaning to ensure uniform cleaning results and reduce uncertainties in human operation.

2. Easy to verify and save records for easy traceability management.

3. Reduce staff risk and avoid injury or infection during manual cleaning.

4. Cleaning, disinfection, drying and automatic completion, reducing equipment and labor input, saving costs

——-Normal washing procedure

Pre-washing → washing with Alkaline detergent under 80°C → rinse with Acid detergent →rinse with tap water → rinse with pure water→rinse with pure water under 75°C→drying

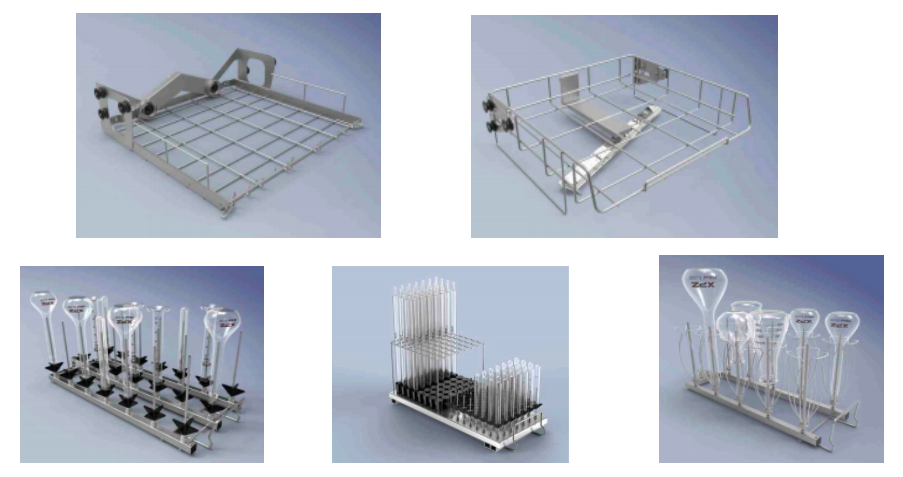

Technological Innovations: Modular basket design

It is divided into upper and lower cleaning baskets. Each layer of the basket is divided into two (left and right )modules. The module is arranged with automatic closing mechanical valve device. It can also be placed on any layer without changing the basket structure.

Importance:

1: More extensive cleaning, can wash more varieties of glasswares

2: There are four seats at the same time in the upper and lower layers, and four modules can be placed at the same time

3: Free combination according different bottles.

4: Cleaning costs decrease

5: Each layer (upper or lower) can be cleaned separately, especially the lower layer, which can be cleaned directly after placing the module

Efficient drying

1.In situ drying system

2. Built-in HEPA high efficiency filter to ensure the cleanliness of dry air;

3. Synchronize the drying water circulation pipeline to avoid the pipeline contamination of the cleaning system;

4. Double temperature control to ensure drying temperature;

Operation management

1.Wash Start delay function: The instrument comes with appointment time start & timer start function to improve the customer’s work efficiency;

2. OLED module color display, self-illumination, high contrast, no viewing angle limitation

4.3 level password management, which can meet the use of different management rights;

5. Equipment fault self-diagnosis and sound, text prompts;

6. Cleaning data automatic storage function (optional);

7.USB cleaning data export function (optional);

8. Micro printer data printing function (optional)

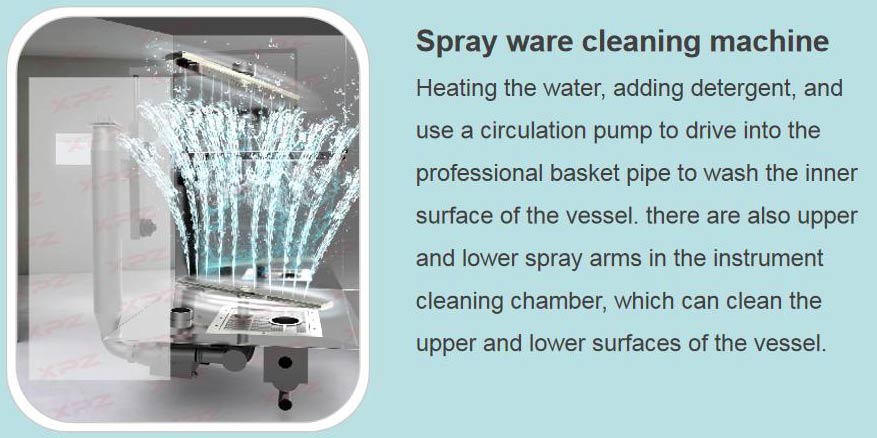

Automatic glassware washer—principle

Heating the water, adding detergent, and use a circulation pump to drive into the professional basket pipe to wash the inner surface of the vessel. there are also upper and lower spray arms in the instrument cleaning chamber, which can clean the upper and lower surfaces of the vessel.

Specification:

| Basic Data | Functional Parameter | ||||

| Model | Flash-1 | Flasht-F1 | Model | Flash-1 | Flasht-F1 |

| Power Supply | 220V/380V | 220V/380V | ITL automatic door | Yes | Yes |

| Material | Inner Chamber 316L/Shell 304 | Inner Chamber 316L/Shell 304 | ICA Module | Yes | Yes |

| Total Power | 5KW/19KW | 9KW/23KW | Peristaltic Pump | 2 | 2 |

| Heating Power | 4KW/18KW | 4KW/18KW | Condensing Unit | Yes | Yes |

| Drying Power | N/A | 1KW | Custom Program | Yes | Yes |

| Washing Temp. | 50-93℃ | 50-93℃ | OLED Screen | Yes | Yes |

| Washing Chamber Volume | 308L | 308L | RS232 Printing Interface | Yes | Yes |

| Cleaning Procedures | 35 | 35 | Conductivity Monitoring | Optional | Optional |

| The Layer Number of Cleaning | 3 layers(Petri dish 4 layers) | 3 layers(Petri dish 4 layers) | Internet of Things | Optional | Optional |

| Pump Washing Rate | 900L/min | 900L/min | Dimension(H*W*D)mm | 1385*935*775mm | 1385*935*775mm |

| Weight | 200KG | 225KG | Inner cavity size (H*W*D)mm | 990*540*550mm | 990*540*550mm |

Our company originated from a story that happened around the founder . The founder’s elder is working in a laboratory as a cleaner. He is in charge of manual cleaning on all kinds of glasswares. He found that the instability of manual cleaning often affected the experimental results, and long-term cleaning and cleaning process also bring physical harm to the health. The founder believe that such risky cleaning should be done inside of a closed cavities to ensure the safety of the cleaner. Then our simple Lab Dishwasher came out. In 2012, with more and more knowledge on the cleaning field, more professional demands are passed on to the founders and partners. In 2014, XPZ have the first generation glassware washer. In 2018, XPZ have the second generation Lab Washer