With the development of economy and society, in order to meet various needs, so industries or fields such as CDC, food testing, pharmaceutical companies, scientific research institutions, ecological environmental protection, water systems, petrochemical systems, power supply systems, etc all own laboratory. At the same time, almost every laboratory has encountered the same problem, that is, the accuracy of the experimental results always inaccurate! This is really a big problem.

The reasons for this phenomenon can be summarized as follows:

(1) Laboratory rules and regulations urgently need to be improved

A mature laboratory must have a set of rigorous and enforceable rules and regulations. This is very important. If there are situations in which experimenters operate in violation of regulations during the experiment, improperly kept equipment, lax experimental records, and damaged experimental environment, of course, it will directly or indirectly affect the accuracy of the experimental results.

(2)The quality of the instrument samples and reagents required for the experiment is unqualified

Although many laboratories have docked with long-term cooperative suppliers, they did not complete the acceptance work in time when receiving these supplies. Some experimental instruments, especially measuring instruments such as test tubes, measuring cups, triangular flasks, and volumetric flasks, have not been found to be unqualified after repeated tests. In addition, the phenomenon of defective medicines, reagents, and lotions is relatively hidden and not easy to detect. The consequences of these problems will be fed back to the final experimental data.

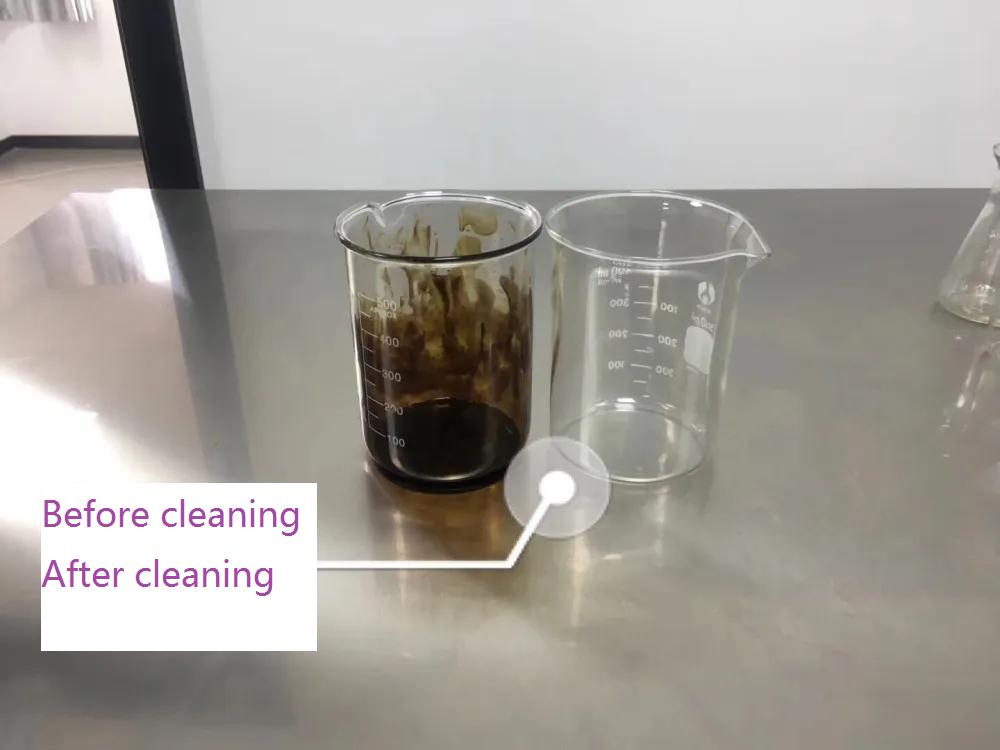

(3) Problems with cleaning of laboratory instruments and utensils

Residual-free cleaning is a prerequisite for accurate experimental analysis. However, many laboratories are still doing manual cleaning work. This is not only inefficient, but also leads to difficult and difficult experimental results standards and statistics. According to an authoritative survey data, more than 50% of the accuracy of experimental results is directly related to the cleanliness of the utensils used in the experiment.

Therefore, relevant parties can make thorough improvements based on the above factors, which will effectively improve the overall level of the entire laboratory including the accuracy of experimental results.

First of all, it is necessary to improve the system of all aspects of the laboratory, do a good job in establishing and training the relevant awareness of the experimental team members, and implement responsible supervision. Fill in experimental records, issue inspection results, and use this as a basis for rewards, punishments and reviews when disputes arise.

Secondly, store, label, and inspect commonly used medicines and glassware. If it is found that the quality is suspicious, it should be reported to the relevant departments and leaders for handling in time to ensure that the experiment is not affected.

Third, use the fully automatic glassware washer to replace manual washing operations. Machine-based, batch-based, and intelligent cleaning of laboratory utensils is the general trend. At present, more and more laboratories in our country have activated the laboratory cleaning and disinfection system for cleaning and sterilizing them. Related cleaning machines, such as a series of products produced by Hangzhou XPZ, not only have humanized operation, save labor, water and electricity energy, more importantly, the cleaning efficiency is very good-the entire process is standardized, the results are consistent, and many The data is traceable. In this way, the preconditions for the correctness of the test results are provided to a considerable extent.

Post time: Aug-06-2020