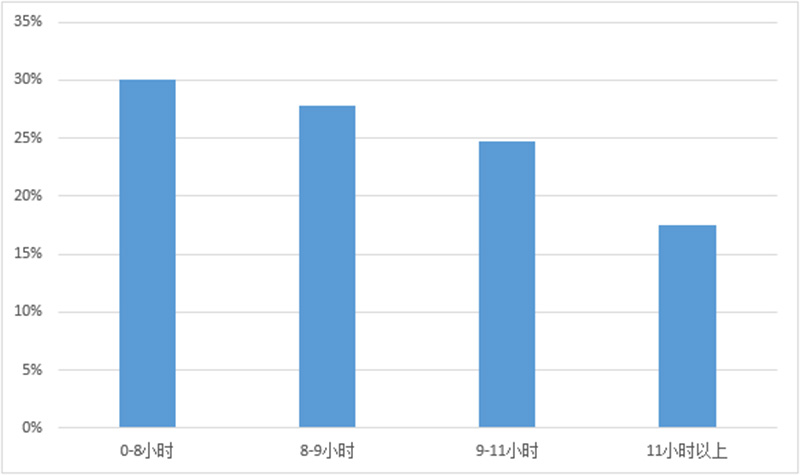

The percentage of time that researchers spend in the laboratory per day

The above picture is a statistics on the proportion of scientific research personnel in the laboratory a day, of which 70% of the time in the laboratory doing experiments, reading documents, and writing reports are more than eight hours, and even 17.5% of scientific research “giants” reach For more than 11 hours. So how do you free up time to clean the glass bottles and dishes used in one day’s experiment? How to ensure that after a day of high-intensity scientific research, the washed bottles and dishes can meet the cleaning standards, so as not to affect the next experiment?

Put down the brush and bottles in your hand, turn off the faucet, and take a look at the automatic glassware washer. You will regret not being able to use the laboratory glassware washer earlier!

Modular design of modules, free collocation

Question: There are many type of bottles in our laboratory, including volumetric flasks, beakers, sample injection vials, etc. Is one glassware washer can meet these cleaning needs at the same time?

Question: There are many type of bottles in our laboratory, including volumetric flasks, beakers, sample injection vials, etc. Is one glassware washer can meet these cleaning needs at the same time?

Answer: Of course, the Lab Washing Machine adopts modular modular design. The cleaning module can be changed according to the type of bottles to be cleaned. For different cleaning situations, the system has 35 fixed programs and one hundred of customizable built-in programs. The program truly realizes whatever you want and can be matched freely.

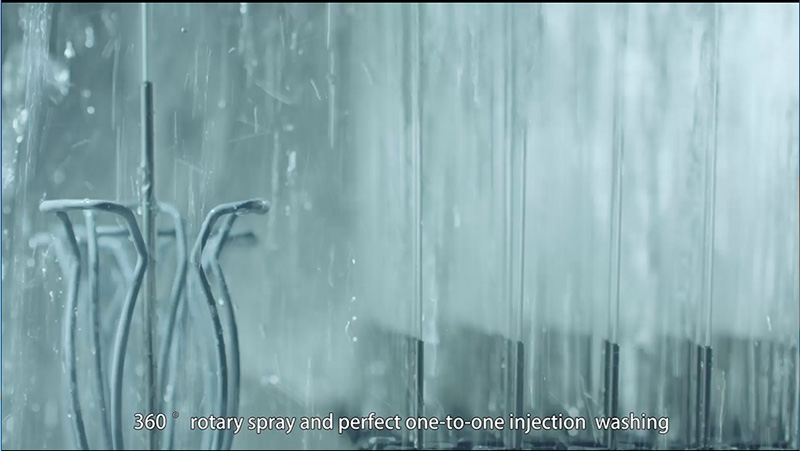

Combination of spray arm and one-to-one injection nozzle

Question: What is the cleaning method of Lab glassware washer ? How do you ensure that it can be cleaned?

Answer: The upper and lower chambers are equipped with two 360° rotating spray arms to clean the outer surface of the bottles and dishes, and one-to-one injection nozzles are used to clean the inner surfaces of the bottles and dishes, so as to achieve all-round cleaning of the inner and outer surfaces of the bottles and dishes. . How to ensure that it can be cleaned? The cleaning procedure includes pre-washing, alkaline main washing, acid neutralization, and pure water rinsing. The optional conductivity monitoring and printer system provides real-time data to achieve effective cleaning of bottles and dishes and data recording and tracing.

Microcomputer control and basket identification technology greatly save cleaning costs

Compared with manual cleaning, the cost of machine cleaning can save about 1/2.

In-situ drying and automatic door opening function highlights the humanized design

Q: Is it just cleaning? Is there any features?

Answer: In order to meet the needs of users for drying after cleaning, the equipment can be equipped with an in-situ drying function. After cleaning, it can automatically enter the drying process as required. It is equipped with double-layer HEPA filter cotton to further ensure drying. The purity of the air in the process. After cleaning and drying, the door will automatically open to a certain position for one minute through ITL induction technology to reduce the temperature in the cavity after cleaning and drying. Prevent personnel from being scalded by hot air, highlighting the humanized design.

The road of scientific research is long, and the glassware washer will accompany with you!

Post time: Oct-21-2021