Introduce the principle of the laboratory glassware washing machine and the seven functions of the three major systems

Automatic Glassware Washer is a set of automatic cleaning, drying function as one of the high-tech products. It can replace the manual cleaning and drying of various laboratory glassware, a variety of programmable programs, one-key start cleaning method greatly reduces the ineffective workload of scientific researchers, while increasing the stability and consistency of batch-to-batch cleaning, especially in environmental protection testing, biopharmaceuticals, food and drug testing and other industries.

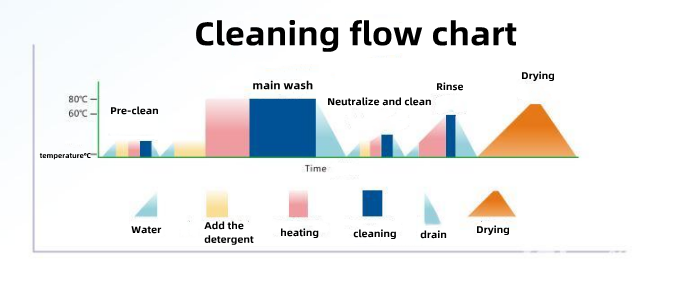

Glassware Washer working principle:

With tap water and pure water (or softened water) as the working medium, using a specific cleaning agent, driven by the circulation pump, the cleaning liquid is directly washed 360 ° inside and outside the vessel by rotating the spray arm and the spray pipe, so as to peel off, emulsify and decompose the remaining substances on the vessel under the action of mechanical and chemical forces; In addition, the cleaning liquid can be automatically heated, and then the utensils can be hot cleaned and disinfected to achieve a better cleaning effect. If the model with drying function is selected, the sample bottle can also be hot air dried after washing to avoid secondary contamination caused by not being removed in time

The Laboratory Glassware Washer has automatic cleaning and drying and other shortcut functions, and its entire operation process is mainly composed of three major systems, which are introduced as follows:

1. Conductivity online monitoring system

During the cleaning process, even a very small residue in pure water can seriously affect the cleaning results. The bottle washer sets the system alarm function, if the conductivity in the last cleaning session exceeds the customer’s set value, the equipment will automatically re-wash. The new maintenance-free online conductivity monitoring system from the bottle washer eliminates the need for additional costs for maintenance and calibration. The system is integrated in the water circulation pathway and does not have direct contact with the water system, which is very accurate.

2. Cleaning agent liquid quantity monitoring and control system

The cleaning agent liquid volume monitoring and control system increases the safety of the system. When adding detergent chemistry, the system shields the effects of liquid viscosity and ambient temperature on liquid flow characteristics, enabling more precise liquid volume distribution. The simple flowmeter control method used in the past was affected by environmental factors. The new technology of the bottle washer has greater accuracy and safety.

3. Spray arm flow rate induction control system

With high-pressure spray cleaning function, that is, spray arm flow rate induction control system, the bottle Laboratory Washer can automatically identify the loaded basket system, and accurately control the speed of the spray arm in the cleaning chamber. If the loading is wrong, the bottle washer detects the error at the beginning of the program and suspends the work. During the cleaning process, the bottle washing machine detects the speed of the spray arm to ensure that the speed is within the set range, so as to achieve a better cleaning effect.

Glassware washing machine for laboratories features:

1. Height adjustable bracket to ensure effective cleaning of different specifications of utensils;

2. Double water temperature control to ensure the entire cleaning water temperature;

3. The cleaning liquid can be set and automatically added;

4. After cleaning, it can be dried in situ;

5. Imported high-efficiency circulation pump, stable and reliable cleaning pressure;

6. Arrange the cleaning position according to the principle of fluid mechanics to ensure the cleanliness of each item;

7. The rotating spray arm of the optimized design of the high-density nozzle ensures that the spray is covered without dead angles at 360 °

Post time: Mar-04-2022