Food safety issues are related to everyone’s health, so it has been the focus of public attention always. Especially in recent years, with the rich material conditions of the people and the continuous improvement of living standards, the demand for food testing has continued to increase.

In fact, food testing and traceability work is generally divided into two categories: one is for sanitation items, and the other is for quality items.

However, no matter which type it is, it is necessary to ensure the accuracy of the test results, otherwise it will not be possible to develop further analysis and demonstration. In addition, except to the samples to be tested, if there is a problem with water, reagents, or glassware in the process of food inspection in the laboratory, then the authenticity of the food test results will be questioned.

The basic steps of food safety inspection

Food safety testing is the use of basic theories and technical methods including physics, chemistry, biology and other disciplines to inspect, determine and analyze the main ingredients, status, and microbiological status of raw materials, auxiliary materials, semi-finished products, finished products, and by-products. The basic steps include:

① Collect samples: confirm the purpose of the test, formulate the test scope and specific sampling objects.

② Preparation of samples: Put the sampled samples into clean sample bottles, and mark the sample bottles according to the serial numbers on the samples. The marks made should be able to identify the state of sample inspection. Prepare sample pre-processing to configure sample curve and sample detection solution.

③Test samples: With the help of related instruments, the reagents or standard solutions and the test solution will be tested at the same time. After calculating the test results and obtaining the original records, the test report can be written.

In this process, water, reagents, and glassware play different roles.

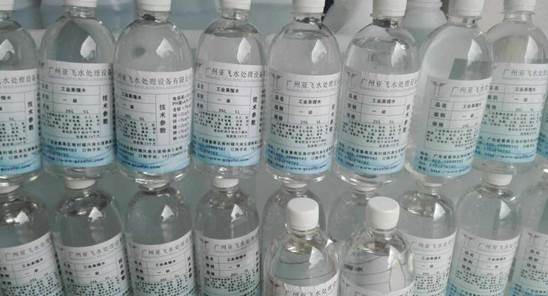

Water: Specially prepared pure water and distilled water are an indispensable element in the food inspection process. In general test items, such as reagent preparation and testing process stage, use ordinary distilled water as the main choice. It is worth noting that when some trace element determination is carried out, the sensitivity of the distilled water needs to be processed again before it can enter the next step of food testing.

Reagents: The reagents in the test should be used reasonably to directly affect the scientificity and accuracy of the food inspection results. Special attention should be paid to the shelf life of chemical reagents. The concentration and quality need to be calibrated regularly, and the use of expired chemical reagents is prohibited, otherwise it will affect the accuracy of the detection effect. In addition, titrating the solution in strict accordance with relevant specifications can further reduce the risk of reagent failure.

Glassware: At present, glass bottles or polyethylene products are mainly used in food testing experimental containers, which can be used to store drugs, transport drugs, and test drugs. Such as test tubes, beakers, volumetric flasks, weighing flasks and Erlenmeyer flasks. But the most important thing is to ensure that the cleanliness and leak-proofness of these glass containers comply with relevant standards and specifications. Therefore, the container for the test product must be thoroughly washed and cleaned before use to ensure that no impurities remain. The role of glassware is almost throughout most important aspects of food inspection.

What are the residual contamination that often occurs in food testing? Can it be cleaned?

Any food testing experiment project will more or less produce residual contaminants in glassware, such as microbial flora, pesticide residues, formaldehyde, heavy metals, proteases, food additives, nutritional fortifiers, reagent residues in the test experiment , Washing activator during cleaning, etc. Therefore, the glassware must be cleaned before the next use. But this process is not necessarily limited to manual cleaning. Given the large quantity, variety, shortage of manpower, and tight time, let’s take a look at the advantages of lab washing machine produced by Hangzhou Xipingzhe Instruments Technology Co.,Ltd ? For example, the cleaning effect is not only more reliable and accurate than manual cleaning, but also recordable, verifiable, and repeatable! Coupled with intelligent automatic glassware washer to control the cleaning process, it is more conducive to the overall improvement of the efficiency of the entire food testing experiment and safety assurance.

In short, to enhance the accuracy of food testing results is the direction that the food testing industry continues to achieve. To make the food safety evaluation results consistent with the real test data, any one of water, reagents, and glassware is indispensable. In particular, the cleaning of glassware washer can continuously improves the cleanliness to meet the expected standards of food testing experiments. Only in this way can it be effectively used as an objective and correct reference basis. I hope food inspectors will keep this in mind, and don’t let the food safety inspection work fall short or ruined because of glassware cleaning.

Post time: Jan-28-2021