OEM Factory for Vials Washer - Laboratory Glassware Washing Machine with in-Situ Drying Function 3-4 Layers Cleaning Capacity up to 308L – Xipingzhe

OEM Factory for Vials Washer - Laboratory Glassware Washing Machine with in-Situ Drying Function 3-4 Layers Cleaning Capacity up to 308L – Xipingzhe Detail:

Product Description:

Flash-1/F1 Laboratory glassware washer,Three – layers cleaning independent installation,It can be connected with tap water & pure water. The standard process is to use tap water & detergent to do mainly wash, then use Pure water rinsing, it will bring you a convenient and fast cleaning effect. When you have drying requirements for cleaned utensils, please choose Flash-F1.

Quick Details

| Brand Name: | XPZ | Model Number: | Flash-F1 |

| Place of Origin: | Hangzhou,China | Overall Power Consumption: | 10KW or 24KW |

| Washing Chamber Volume: | 308L | Material: | Inner Chamber 316L/Shell 304 |

| Water Consumption/Cycle: | 23L | Power Consumption-Water Heating: | 4KW or 18KW |

| Washer Chamber Size(H*W*D)mm: | 990*540*550mm | External Size(H*W*D)mm: | 1385*935*775mm |

| Gross Weight(kg): | 225kg |

Packaging&Delivery

Packaging Details : Wooden Package

Port : Shanghai,China

Automatic Glassware Washer

Features:

1. Can be standardized for cleaning to ensure uniform cleaning results and reduce uncertainties in human operation.

2. Easy to verify and save records for easy traceability management.

3. Reduce staff risk and avoid injury or infection during manual cleaning.

4. Cleaning, disinfection, drying and automatic completion, reducing equipment and labor input, saving costs

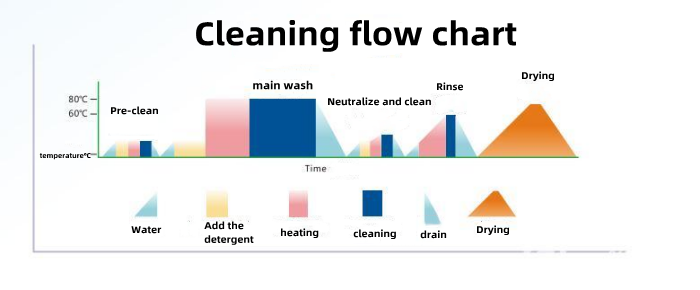

——-Normal washing procedure

Pre-washing → washing with Alkaline detergent under 80°C → rinse with Acid detergent →rinse with tap water → rinse with pure water→rinse with pure water under 75°C→drying

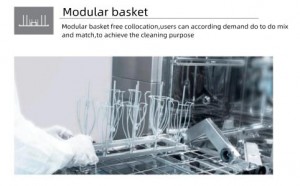

Technological Innovations: Modular basket design

It is divided into upper and lower cleaning baskets. Each layer of the basket is divided into two (left and right )modules. The module is arranged with automatic closing mechanical valve device. It can also be placed on any layer without changing the basket structure.

Importance:

1: More extensive cleaning, can wash more varieties of glasswares

2: There are four seats at the same time in the upper and lower layers, and four modules can be placed at the same time

3: Free combination according different bottles.

4: Cleaning costs decrease

5: Each layer (upper or lower) can be cleaned separately, especially the lower layer, which can be cleaned directly after placing the module

Efficient drying

1.In situ drying system

2. Built-in HEPA high efficiency filter to ensure the cleanliness of dry air;

3. Synchronize the drying water circulation pipeline to avoid the pipeline contamination of the cleaning system;

4. Double temperature control to ensure drying temperature;

Operation management

1.Wash Start delay function: The instrument comes with appointment time start & timer start function to improve the customer’s work efficiency;

2. OLED module color display, self-illumination, high contrast, no viewing angle limitation

4.3 level password management, which can meet the use of different management rights;

5. Equipment fault self-diagnosis and sound, text prompts;

6. Cleaning data automatic storage function (optional);

7.USB cleaning data export function (optional);

8. Micro printer data printing function (optional)

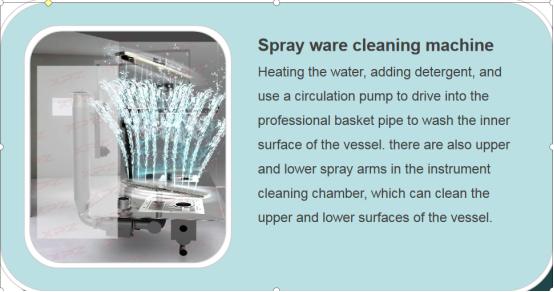

Automatic glassware washer—principle

Heating the water, adding detergent, and use a circulation pump to drive into the professional basket pipe to wash the inner surface of the vessel. there are also upper and lower spray arms in the instrument cleaning chamber, which can clean the upper and lower surfaces of the vessel.

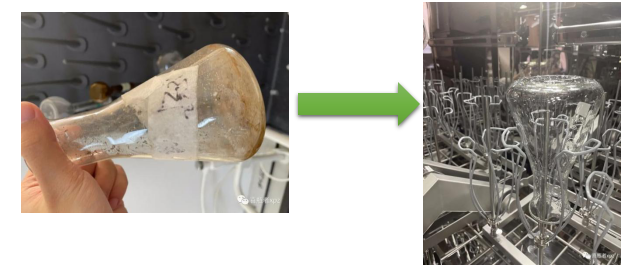

Cleaning effect

Hangzhou Xipingzhe Biological Technology Co., Ltd

XPZ is a leading manufacture of laboratory glassware washer,located in hangzhou city,zhejiang province,china.XPZ specializes in research,production and trade the automatic glassware washer which is applied to Bio-pharma,Medical health,Quality inspection environment ,food monitoring,and petrochemical field.

XPZ is committed to help solve all kinds of cleaning problems.We are the main supplier to Chinese inspection authorities and chemical enterprises,meanwhile XPZ brand has been spread to many other countries,like india ,UK,Russia,South Korea,Uganda,the philippinese etc.,XPZ provides integrated solutions based on customized demand,including product selection ,installation and operate training etc.

We will gather more enterprise advantage to provide innovtive products with high quality and excellent service ,to keep our long-term friendship.

Certifications

Product detail pictures:

Related Product Guide:

We support our consumers with ideal good quality merchandise and large level provider. Becoming the specialist manufacturer in this sector, we have attained wealthy practical encounter in producing and managing for OEM Factory for Vials Washer - Laboratory Glassware Washing Machine with in-Situ Drying Function 3-4 Layers Cleaning Capacity up to 308L – Xipingzhe , The product will supply to all over the world, such as: Pakistan, panama, Bulgaria, We believe that good business relationships will lead to mutual benefits and improvement for both parties. We have established long-term and successful cooperative relationships with many customers through their confidence in our customized services and integrity in doing business. We also enjoy a high reputation through our good performance. Better performance will be expected as our principle of integrity. Devotion and Steadiness will remain as ever.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.